GGSEU launch a new "DIY" PPE visor kit to help meet increasing demand

Robyn Turner • 20 April 2020

Gardiner Graphics Group, the UK’s largest independent conversion facility within the lamination and print industry, having recently re-purposed its resources into the manufacturing of PPE takes further steps to meet demand with a "DIY" kit.

Managing Director Will Duggins commented of the move“It truly has been a momentous two weeks for the Gardiner Graphics Group with all available resource moving over to the preparation and assembly of our emergency PPE visors. The commitment and hard-work from the team has been astounding in such a critical time of need”

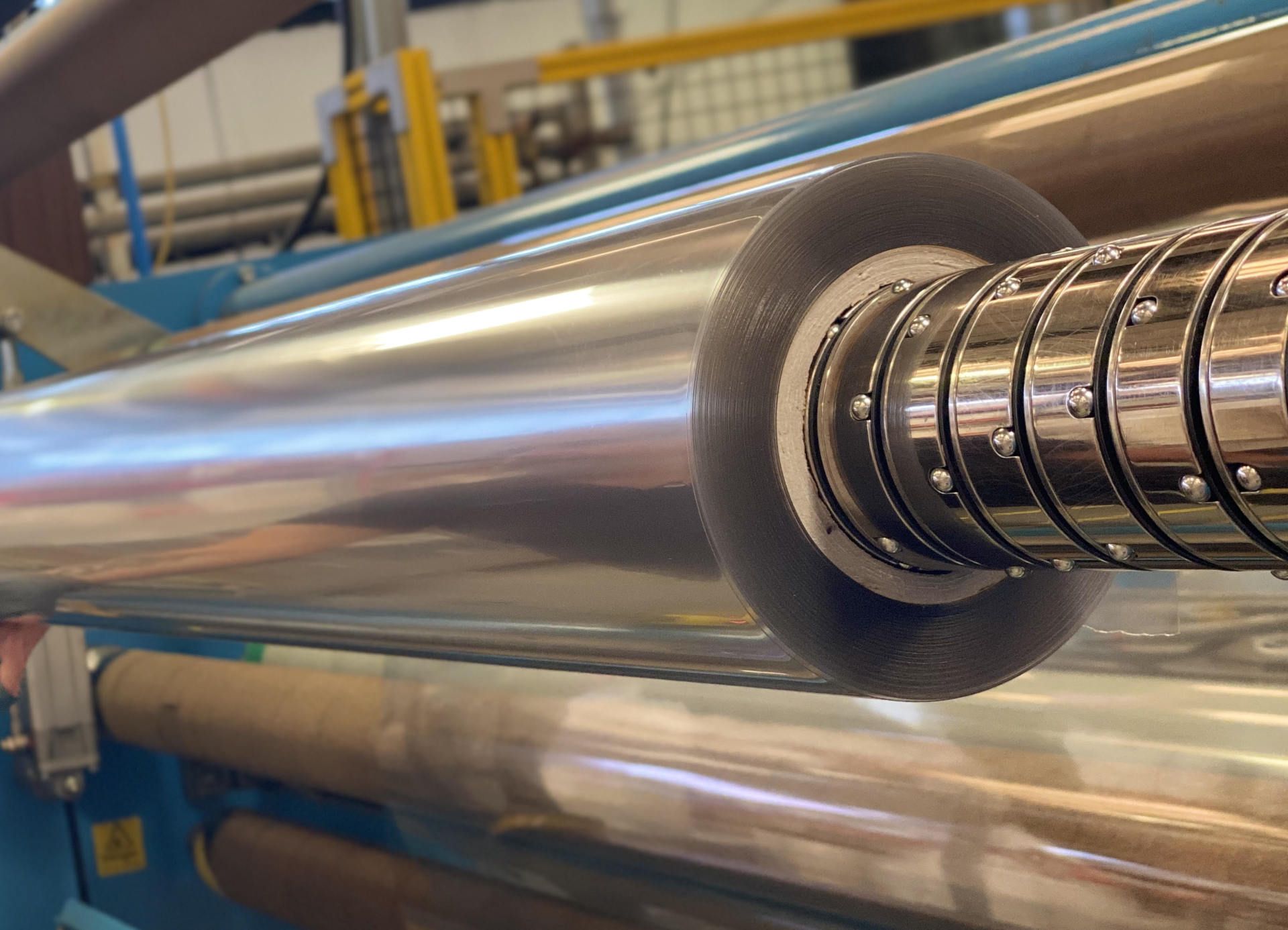

Gardiner Graphics Group are manufacturing up to 20’000 units per day along with over 5 tonnes of prepared PET sheets to other manufacturers applying their own designs.

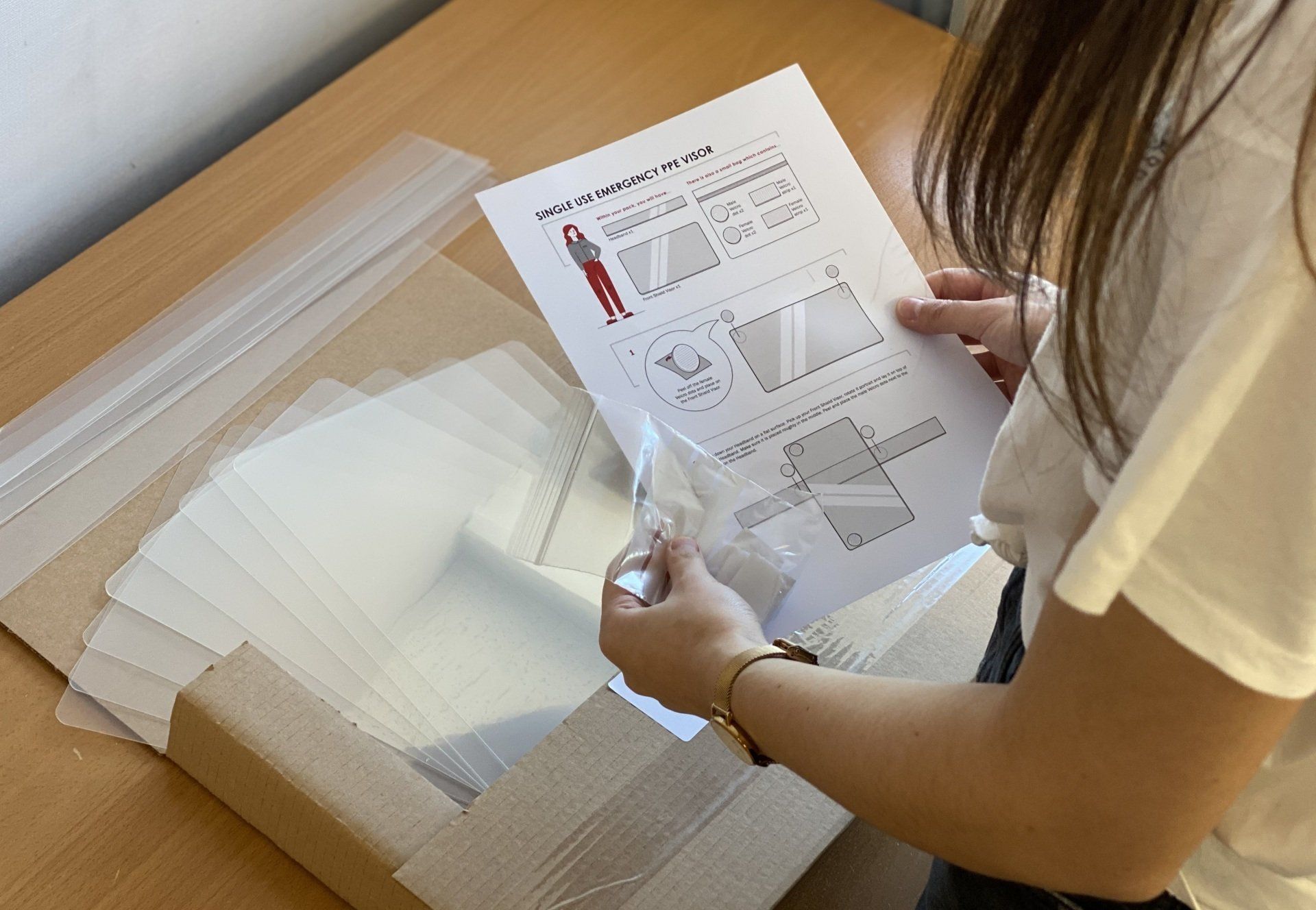

The latest move from the Gardiner Graphics Group sees the offering of a DIY visor kit, delivered as a pack of components where the key worker can assemble their visor upon delivery within moments. The DIY kit reduces production

time by 60%, resulting in greater volumes of the personal protection equipment reaching key environments in good time.

Will Duggins went on to explain “we are confident now that with the complete visors, the prepared flat-sheets and now this DIY kit - we have something for everyone. There really is no reason for any key worker to feel vulnerable or at risk. We have the stock, we have the solutions, we have the capacity to meet the demand".

Single Use Emergency PPE Visor - DIY Kit

Flat packed, self-assembly single use, clear visor to protect the eyes, nose, mouth and face from contaminated COVID-19 droplets. For emergency use in key working environments.

Each kit contains:

The company urge any known contacts that may benefit from these items to please reach out to discuss the immediate supply.

The Gardiner Graphics Group appoint a new European sales team, setting their sights firmly on raising profile of their manufactured products, including that of new development Touchshield™ , throughout EMEA territories. Touchshield™ is the latest development from the Gardiner Graphics Group. A unique range of clear, water-marked anti-microbial self-adhesive protective films designed to slow the spread of bacteria and viruses. The protective film, manufactured in the UK at their Banbury facility recently obtained the highly esteemed ISO 21702, reaching efficacies of up to 93.41% against viral activity. CEO Tom Powell commented “we truly believe that our new developments can support all businesses in all sectors. I am delighted to have our new team aboard and look forward to seeing them fly the flag for our products”.

Gardiner Graphics Group is recognised as a #GREATinspiration as part of the Great Britain & Northern Ireland Campaign. The Great Britain & Northern Ireland Campaign launches #GREATinspiration, an initiative designed to shine light on those who have done extraordinary things during the COVID-19 pandemic. The GREAT Inspirations celebrates businesses that continued to operate for their customers, support their employees and innovativley adapt to a new way of business. In March 2020, with a natural downturn in activity within their sector, Gardiner Graphics Group re-purposed its materials and machinery into the manufacturing of PPE visors. CEO Tom Powell commented “ with such a vast stock of PET right here in the UK and the machinery suited to the job, we recognised the increasing demand for PPE items and wanted to help and wanted to make sure that our Portsmouth manufacturing facility kept moving. To have all the materials and equipment to re-purpose into a much-needed item seemed the right thing to do.” The team quickly started producing up to 20k single use emergency visors per day distributing daily to key workers in a range of sectors. Alongside visor production, the company working tirelessly to deliver over 200 tonnes of recyclable PET in reel and sheet format to other UK businesses looking to apply their own PPE designs, ensuring that other business alike could keep working and keep delivering much needed PPE items.

Roland DG EMEA Announce Integration Partnership With Media Experts Gardiner Graphics Supplies Europe (GGSEU) GGSEU, a leading supplier of graphic materials within the UK, has been enlisted to manage and further develop a new and progressive Roland DG media programme, proudly serving Europe, Middle East and Africa (EMEA). The UK firm, having undertaken substantial investment in the last 2 years to increase its manufacturing capabilities, comes with over 35 years’ experience within product R&D and media distribution within the wide format sector. The partnership has been initiated to further provide a complete and saleable solution in which the Roland DG machines and media work harmoniously for optimised end-results.

CAUTION: Are your floor vinyls slip-rated? It's all about floor graphics right now as social distancing becomes the 'new normal'. As public spaces slowly re-open and people return to work, the demand for social distancing messages has surged beyond any expectations within our sector. Consumers need effective, safe ways to convey messages and printers are looking for availability on products that they can trust will do the job.

More than ever we are being asked the question “how can I keep my printed graphics clean and germ-free without damaging them?” We wanted to put together some handy tips so that all those out there in key environments know how to best clean down their laminated book covers, menus, printed signs and retail POS whilst maintaining their quality and purpose. What is your laminate or printed graphic made from?

Gardiner Graphics Supplies Europe (GGS EU), the UK’s largest independent conversion facility in the lamination and print industry, announce a unique 100% PVC-free wide format print media for Latex and UV printing. Having brought wide format print media manufacturing in-house with a newly installed coating line, GGS EU announce their first nod to sustainable products with WP300 PP. This new 100% PVC-free media has been designed with wall applications in mind but also provides the perfect solution for external signage and industrial label applications. Recently appointed EMEA Sales Director Matt Littler says…

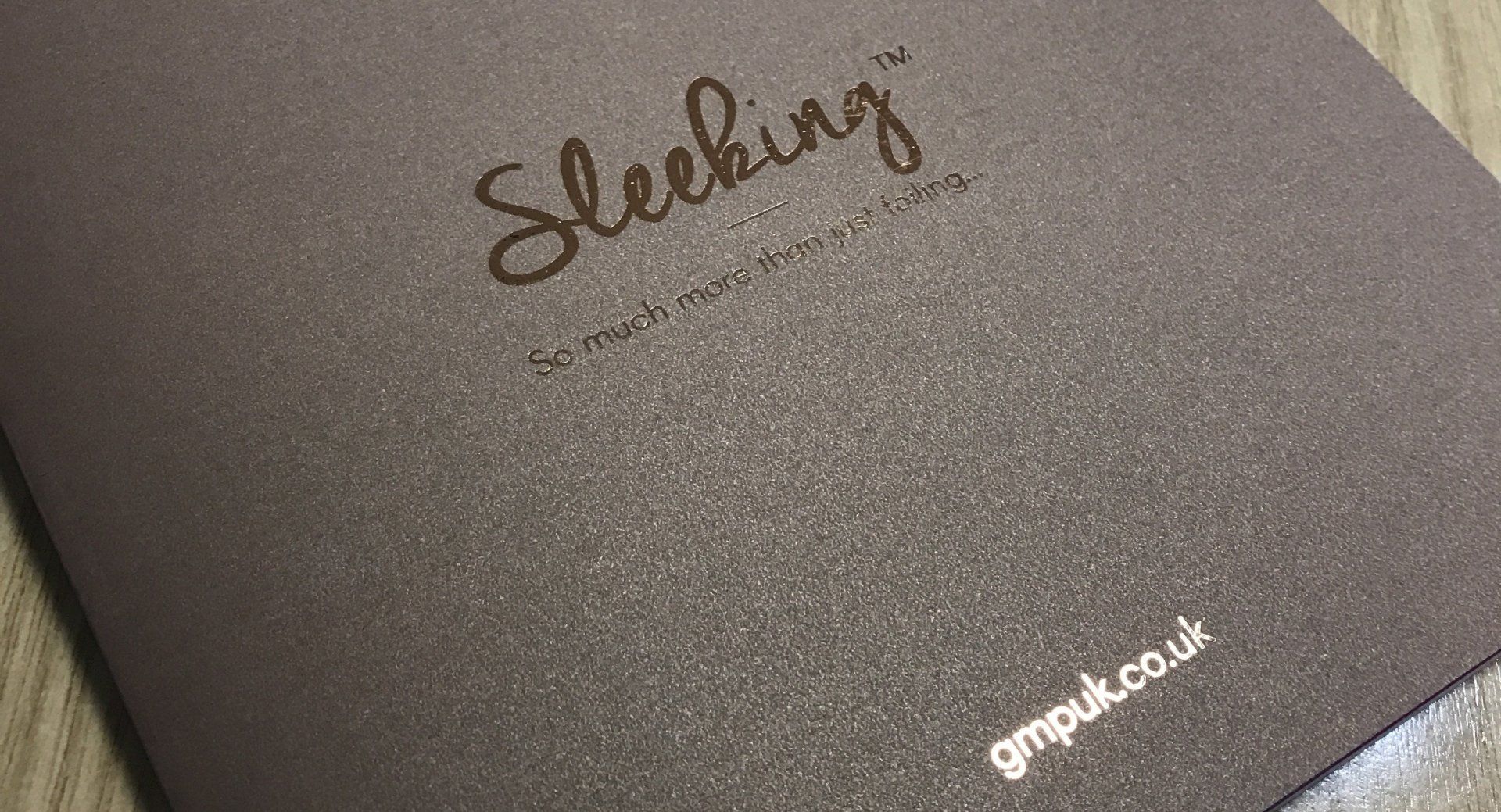

Sleeking™ is an on-demand, digital foiling process that creates impressive special effects without the need for special dies and expensive block foiling. This technology, originally from South Korea, has revolutionised the ability to create budget-friendly finishes to rival the effects of any traditional foil stamping. During the Sleeking™ process, toner in the digital print is fused to GMP foils in a GMP Sleeking™ laminating machine with a pneumatic roller set to the correct temperature. All you need is a l aminator and your own digital printer. Why choose Sleeking™?