Want to find the perfect PVC for you? Just think of pizza. No, we’re not joking. Read on to find out why…

Vinyl is a fantastic, hard-wearing, long-lasting material for creating signs and graphics. There are three types of display vinyl: monomeric, polymeric and cast.

All three are polyvinyl chloride – the vinyl we know as PVC – and contain similar ingredients, but the quality of those ingredients and how they are created make all the difference.

Just like pizza. Do you like your pizza base to be thin, doughy, or stuffed crust? As for possible toppings, are you a plain Margherita person or meat feast piled high with extras?

Just like finding your perfect pizza, knowing which PVC you need for your project is key to getting the results your customers will love.

Read on for our guide…

Monomeric film

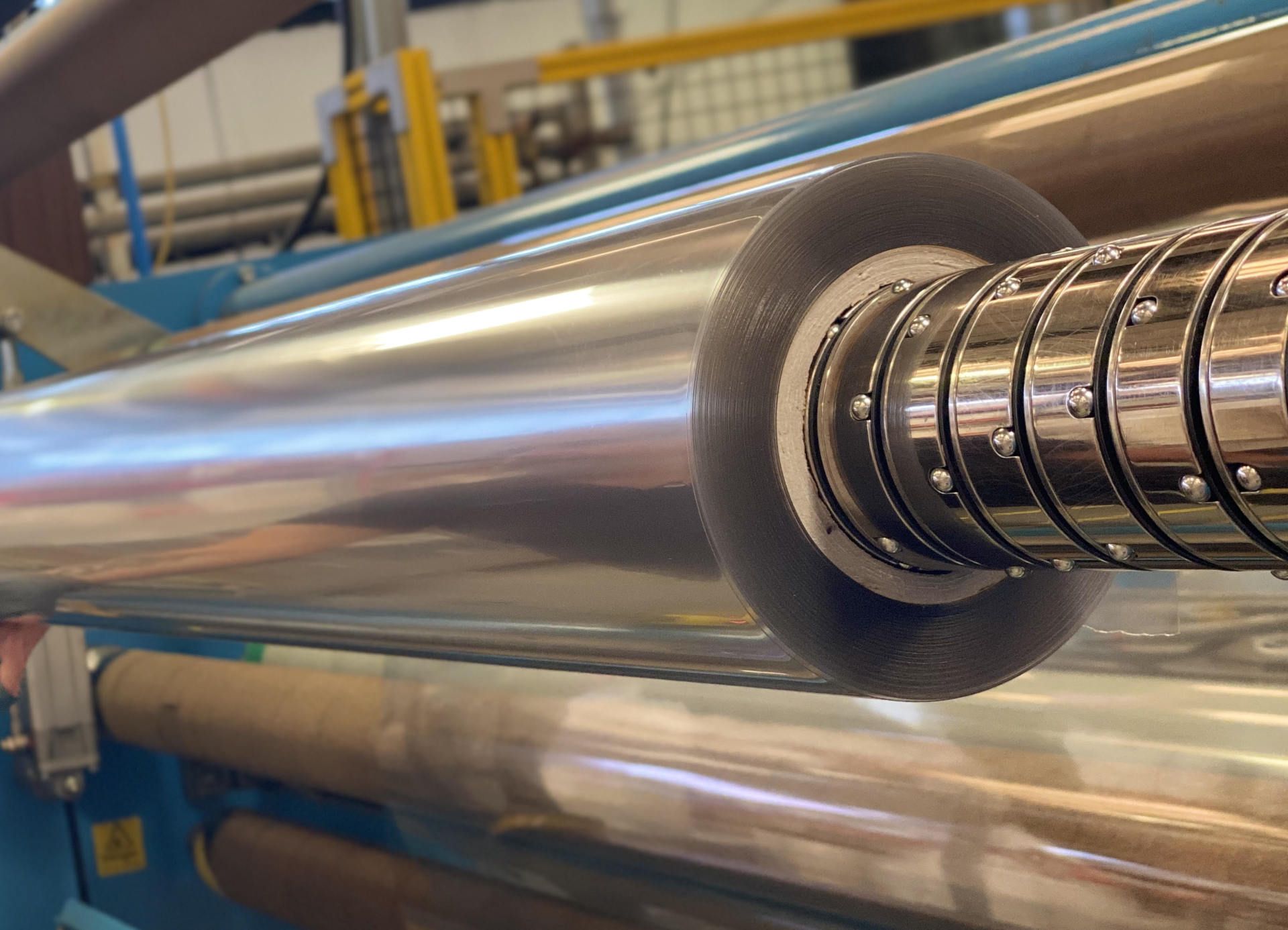

This is one of the cheapest types of PVC on the market, with the lowest cost of ingredients. Monomeric film is stretched or rolled out like pizza dough, to make it thin and printable. This process is known as calendering. All PVC that has been calendered holds the memory of its pre-stretched shape. It really wants to shrink back to its original size, and to stop that happening a cocktail of chemicals is added to its formulation. Most monomeric PVC will last around three years, so for short-term graphics, it is a cost-effective choice.

Polymeric film

This is monomeric film’s more expensive sibling. Although polymeric film is made from similar raw materials and undergoes the same calendering process as monomeric film, it is made from higher quality ingredients. This means it can look great for longer, often around five to seven years. Not only does it live longer, but it can also be used on a wider variety of surfaces. Polymeric film can even be used on surfaces that are not flat or regular, opening up greater project possibilities.

Takeaway tip – Both monomeric and polymeric PVC media are excellent choices for a range of applications, such as pop-up displays, short-term exhibition graphics and Point of Sale promotions.

Cast

Just like a pizza, cast PVC starts with the same raw materials as monomeric and polymeric films. It is what happens next that makes it different.

The highest quality ingredients available are used to manufacture cast. Also, during the production process cast is not calendered. Instead, the PVC is poured into a casting tray so that it is ‘cooked’ flat from the beginning. This means that cast PVC does not want to shrink back to its original size; it is created the shape and size of the container into which it is poured.

This means that there is far greater flexibility for applications when using cast. It can be formed or wrapped into a multitude of different shapes, and because it doesn’t want to shrink back, it will last longer, often more than seven years.

This durable product is perfect for vehicle wrapping or other high-end applications designed to last.

Takeaway tip – Did you know that all types of PVC vinyl are available in gloss and matte finishes and with both white and clear face films? There are so many options for you to create your perfect project.

Want to know more? Contact the Gardiner Graphics Supplies Europe team to discover the best product for your project.

CALL US:

+44 (0) 23 92 22 11 33